Fujita – Osaka Marubiru Redevelopment ProjectThe Whole Story of Marubiru Demolition Work and the Care Taken for Stakeholder Safety and Security

The role Osaka Marubiru performed as a landmark building in the Umeda district of Osaka had come to an end. Subsequently, as one part of the tentatively named Osaka Marubiru Redevelopment Project jointly undertaken by Fujita Corporation and Daiwa House Industry Co., Ltd., the building was demolished from 2023 to 2024. In light of this having been such a unique, cylindrically shaped skyscraper located in the heart of Osaka, here we will introduce the advanced technologies and ingenious solutions implemented to ensure that demolition work progressed safely.

Project overview

Strengths as a former contractor

To safely dismantle the rare, even by the standards of its time, cylindrical, regular fifty-two-sided polygon-shaped building, a major key to success would be having an accurate grasp of its structure and construction methods. Considering this, Fujita, which in 1976 had overseen construction of the then-new Osaka Marubiru, took the lead again, and by reviewing historical documents, construction records, and blueprints, it unraveled the building’s structure down to the finest details.

Valuable information from retired employees

In a time before the advent of personal computers, this building was constructed in an age of handwritten blueprints. During the information gathering stage, we also conducted in-person interviews with retired Fujita employees who had been engaged in the construction. Information not documented in records, such as the challenges of the “twist” in the cylindrical skyscraper, was also put to good use in the demolition project.

A joint project with Daiwa House Industry, leading to the future

This was a major project advanced by Fujita and Daiwa House Industry. The former site of Osaka Marubiru has been provided for use as a bus terminal during Expo 2025 Osaka, Kansai, Japan. Following the event’s conclusion, it is planed to reemerge as a new building. Based on the concept of an “Urban Regeneration Tree,” we are planning an environmentally conscious building that incorporates advanced technologies while retaining its distinctive cylindrical shape. Looking to create new vitality in Osaka, plans are underway for a variety of uses, including hotel services, offices, and concert halls, with completion scheduled for 2030.

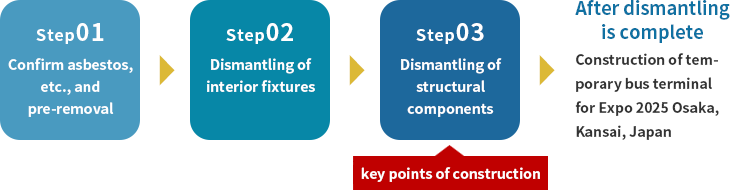

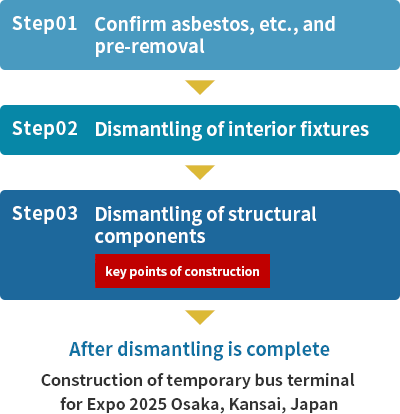

Demolition work flow

The demolition work proceeded in the same sequence as for typical high-rise buildings: first, confirming and removing hazardous materials such as asbestos; next, dismantling interior fixtures like gypsum board and facilities equipment; and finally, demolishing structural components.

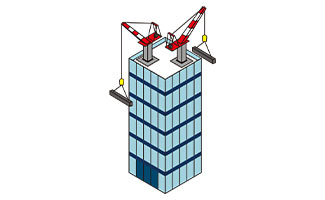

One of the biggest issues faced was the “construction period,” as it was decided that the site would be utilized as a temporary bus terminal during Expo 2025 Osaka, Kansai, Japan. For that reason, it became necessary for a construction period that would normally require two years, to be shortened to one year and six months. Given this, we formulated a plan whereby the structural components would be demolished at a rate of five days per one floor, and thoroughly streamlined work. For loading and unloading components, two tower cranes were operated alternately. By loading the next components while cutting and unloading, we minimized waiting time during operations. Moreover, we employed a two-shift system: during the day, we carried out demolition of structural components such as perimeter slabs and beams, including crushing operations at the ground-level demolition yard; and during nighttime hours, work was limited to quiet operations such as dismantling exterior precast concrete (PC) panels to avoid noise.

Utilizing advanced technical expertise to achieve both safety and reduced time for structural demolition work

1. “Safety is the utmost priority” with climber cutting demolition

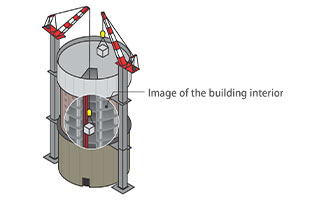

We adopted what is known as a “climber cutting demolition” method to demolish this high-rise building. This method involves cutting an advance opening, known as a drop-through opening, thereby creating a direct route internally within the building from the floor being dismantled to the ground level. Following that, a concrete cutter is used to finely cut the structural points of the floor where dismantling is taking place. Utilizing a high-reach crane, the materials that have been cut out are lowered to the ground via the drop-through opening. After all of the materials have been cut out and removed from that floor, the scaffolding is lowered, and work advances to the next floor to be demolished. While the scaffolding is not dismantled, using Fujita’s Fast Failsafe Climbing Form (FCF) construction technology, a jack is used to lower one floor at a time, thereby mitigating risk for workers who are operating high above ground.

Climber cutting demolition flow

Scene with cutting materials from the floor being dismantled. Use of a concrete cutter means almost no generation of dust and noise.

Materials that have been cut out are lowered to the ground via the drop-through opening made within the building. Precise calculations are made in advance so that the cut materials will be able to pass through the drop-through opening.

The tower crane is equipped with a rotation control device, enabling it to lower the load straight down to the ground.

The area where the lower floors stood was converted into a demolition yard, and crushing operations were conducted on the ground.

Point

Difference from conventional demolition methods

Typically, materials being removed from a building being demolished are lowered on its exterior. However, in the event that damage or other trouble occurs with the materials that are high above ground during unloading operations, even fragments as small as a few centimeters could impact safety on the ground due to the acceleration during their fall. In addition, even when taking a maximum degree of safety precautions, the sight of large pieces of concrete being lowered from high places may cause concern among nearby pedestrians and others. Taking such factors into account, for this demolition we lowered the materials to the ground through the inside of the building.

Illustration of conventional demolition work:

Rubble and other demolished material is lowered to the ground outside of the building

Illustration of climber cutting demolition:

Materials are lowered to the ground through a hole opened internally within the building

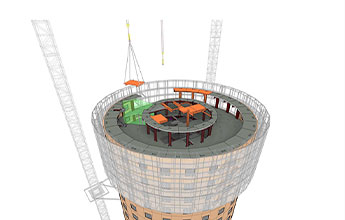

2. The FCF construction method (horizontal lifting robot jack construction system) used to mitigate risks while working high above ground

To raise and lower scaffolding, we adopted a technology developed by Fujita, known as the FCF construction method (a horizontal lifting robot jack construction system). This construction method employs a work platform that integrates scaffolding and external curing (protective) sheets, raised and lowered by multiple hydraulic jacks. Computer control enables it to ascend and descend freely while maintaining a constant horizontal position.S

caffolding can be assembled and disassembled at ground level, reducing the risks associated with working in high places. Furthermore, operations are centrally controlled via a computerized control panel, enabling precise and rapid lifting and lowering without requiring workers with specialized skills. The FCF method can be used in the construction of a variety of structures such as bridges and high-rise buildings. Employing this system substantially raises safety and efficiency, and work progresses more smoothly at construction sites.

For this demolition project, we planned to lower the scaffolding one floor at a time as each floor was demolished, significantly reducing the time required for scaffolding assembly and disassembly.

3. A “thorough pre-simulation” based on demolition plans that utilize BIM

The demolition plan utilized Building Information Modeling (BIM) which simulated the different types of materials to be cut, and whether or not it would fit into the drop-through opening. This enabled all parties involved to share a common understanding of the work, allowing them to proceed efficiently and safely. Although BIM is seldom used in demolition work, in this instance we employed it in our pursuit of a more robust degree of precision and accuracy, as the project demanded meticulous, precise, and safe operations high above ground. Fujita has a track record of employing climber cutting demolition and has cultivated expertise in this area. However, in consideration of workers undertaking this method for the first time, we thoroughly confirmed beforehand all precautions and hazards associated with these operations. Furthermore, process visualization revealed new insights into bottlenecks in workflow, enabling the implementation of countermeasures. This contributed to improved work efficiency even within a tight schedule.

(Both right and left illustrations) Visualizing the BIM image process enables confirmation of efficiency and safety

Safety measures in demolition work on upper floors

The psychological reassurance that comes with “lack of visibility”

We took great care to cover the building with scaffolding and sheeting so that absolutely no work activities were visible from the outside, striving to create a work site that was not only physically safe, but also visually reassuring. Regarding work at high places, ensuring that the building was “tightly covered” facilitated a sense of safety among nearby residents and those who were passing by.

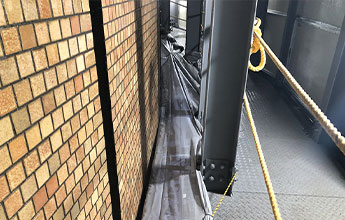

Of course, in anticipation of any unforeseen circumstances, we took measures to ensure that bolts or debris fragments did not go flying, including by addressing the gap between the sheet and the wall. Even if a bolt were to pop off, the design is such that it would be caught by the sheet and, if it falls to the ground, it would pass within the sheet. Establishing these “second and third lines of defense” was how we took every precaution.

Installation of fall prevention curing sheet from the bottom of the FCF scaffolding

Rolling up the net helps to keep objects, even if they fall, within the net

Thorough measures and a mindset to prevent dispersal focused on eliminating third-party accidents

The site of this demolition featured a unique structure built as a regular fifty-two-sided polygon, with scaffolding arranged in a straight-line configuration of regular twenty-six-sided polygons. Therefore, there was an inherent structural issue where gaps inevitably formed at the top of the scaffolding. However, safety was ensured by inserting pliable materials such as rubber or polystyrene foam into these gaps. The work site and the head office came together to seriously address the question, “How can we maximize safety?” In response, we implemented a series of improvements tailored to actual site conditions.

Furthermore, thoroughly implementing detailed safety measures had a positive impact on worker mindset. Over this long-term construction project, consistently demonstrating an unwavering commitment as the prime contractor led to maintaining each worker’s focus and discipline.

Covering gaps around exterior windows with polystyrene foam materials or fire-retardant sheets

Filling and sealing the gap between the flooring edge and the exterior wall with rubber material

Environmental and safety measures in demolition work on lower floors

Noise and dust suppression

The lower floors, which had already been demolished, were used as a crushing yard where we crushed debris that had been lowered from the upper floors. Noteworthy, though, is our work to reduce noise levels by deliberately retaining the outer structural elements of those lower floors. Additionally, the upper section of the crushing yard was designed with dust prevention as the top priority. This involved installing a roof-like curing sheet, while also accounting for the range of movement needed by heavy machinery.

Furthermore, as this project falls under the category of specific construction work subject to noise regulations, at night time we did not use heavy machinery and only performed work that did not generate noise. After cutting the bolts on the exterior PC panels with gas, we lowered the materials using a crane and transported them directly to the disposal site without crushing on the ground level of the site.

The curing sheet roof cover over the crushing yard extending from the external scaffolding

The curing sheet roof cover that allows space for heavy machinery operation

Work to lower the external PC panels to ground level.

Noise is not generated as heavy machinery is not used

In consideration of noise levels, crushing is not conducted on the ground, but material is taken away as is

Securing the safety of workers

We conducted a rigorous survey to check for asbestos prior to the demolition stage. Although asbestos was confirmed to be present in some areas due to the early construction year of the building, it was completely removed before demolition by heavy machinery began.

Additionally, when performing concrete crushing work on the ground level, all personnel are required to wear dust masks. Moreover, such work is performed while spraying water in order to suppress the risk of dust dispersion. Furthermore, when workers responsible for spraying water need to approach crushed materials, they carry mesh screens used as shields to protect themselves from any potential flying debris.

Voice of the Person in Charge

This project moved forward with “securing safety” being of utmost importance. In the vicinity there are hotels and commercial facilities, and this is an area where a multitude of people pass by. We carefully crafted our plans while re-examining the very nature of demolition work itself, ensuring that local residents can live each day with peace of mind. As a result, it is our belief that we have been able to present our own unique solution for the demolition of a high-rise building in an urban area.

Not merely driven by the head office, there were a great many practical ideas provided by members of branch offices and the work site. We feel that this initiative was built by drawing upon the capabilities and expertise of a variety of sources, including personnel who previously worked on dismantling operations and insights from retired employees. The fact that we were able to unite as one—head office, branches, the work site, and specialized contractors—is itself a highly valuable achievement.

Fujita Corporation

Management Reform Division

M-PJ Office

General manager

Takao Nishizawa

The site of this project was a regular fifty-two-sided polygon, a building with an extremely rare structure. From the time we first examined the blueprints we keenly felt the high level of difficulty, but we were overwhelmed by the determination of those who came before us, thinking, “more than anything, it’s amazing they were able to construct such complex, polygonal high-rise buildings back then—something that couldn’t be neatly divided into straightforward numbers.” That is precisely why we, who have been entrusted with this building, also bear the responsibility to firmly continue carrying the baton. We made concerted efforts to implement every possible measure to ensure that all workers involved shared a powerful commitment, such as to “absolutely prevent even a single screw from falling.” As a result, we feel a great sense of accomplishment as a team for completing the project without any accidents.

Fujita Corporation

Management Reform Division

M-PJ Office

Minato Matsuda

* The information is current at the time of interviews (July 2025).