― Supporting disaster-stricken areas

with top-class private-sector performance ―

Public housing that supports recovery from a disaster, also known as “post-disaster public housing,” refers to public rental housing constructed by local authorities for those who have lost their home due to a catastrophic event. At the very foundation of Daiwa House Industry lies an enduring commitment to reconstruction. We are a company that was founded by a man who, being deeply moved by the extensive damage to homes caused by a major typhoon, sought to develop buildings that were both strong yet flexible.

Still today, we strive to construct post-disaster public housing that brings together our business development capabilities and technological prowess against a backdrop of proven top-class private sector performance.

Acquisition of financial resources and budget

Land acquisition

Adherence to systems, laws and regulations

Business planning and proposals

Establishment of systems for construction and operations

Addressing housing needs of disaster victims

Business development capabilities

Municipalities quite often lack experience undertaking projects to develop post-disaster public housing. Such projects consist of emergency response measures and necessitate swift implementation during peak periods of disaster recovery operations, and represent an extremely high level of difficulty.

Daiwa House Industry has over many years accumulated vast experience in post-disaster public housing business schemes and has steadily rolled out projects, primarily in coordination with local communities and municipalities. Within the company, a dedicated department responsible for reconstruction support collaborates with offices based in regions around Japan to establish a system that facilitates smooth progress, even for complex coordination and planning. Depending on the circumstances of the disaster-stricken area, within this framework we can take a wide range of measures, from large-scale and intensive community development, to small-scale rural-type housing construction.

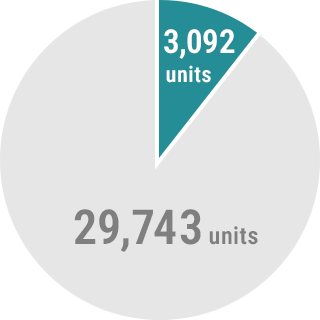

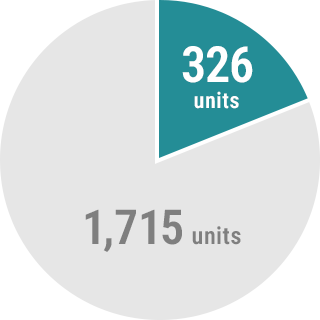

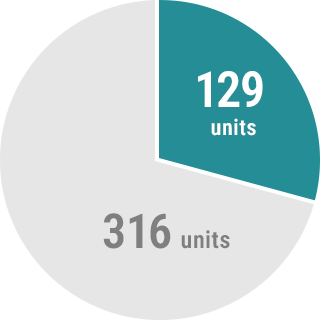

As a result, the numerous post-disaster public housing projects we have engaged in for reconstruction following the Great East Japan Earthquake, the Kumamoto Earthquake, the torrential rains in western Japan, and other disasters have made us the most experienced company in the private sector in terms of both construction and adoption numbers (as of September 2025).

Building on such a track record, we vigorously support reconstruction efforts through the dual strengths of our nationwide corporate capabilities and the great care and on-site responsiveness provided by our bases firmly rooted in Japan’s regions. For a first consultation, please feel free to visit your nearby Daiwa House Industry office.

3,547units

*As of May, 2022

*Daiwa House Industry

*Great East Japan Earthquake, Kumamoto Earthquake,

torrential rains in western Japan, and intense rainfall in July 2020

Great East Japan Earthquake

Kumamoto Earthquake

Torrential rains in western Japan

(Great East Japan Earthquake: “Municipal Uomachi Irizawa Housing” in Kesennuma City, Miyagi Prefecture)

(The intense rains of July 2020: “Kamise Housing Complex” in Kuma-mura, Kuma District, Kumamoto Prefecture)

Technological prowess

Daiwa House Industry is a company that has earned the “No. 1* position in the housing, construction, and real estate industries,” in terms of the Group’s consolidated net sales. As a pioneer of industrialized construction that paved the way for prefabricated buildings, we introduced the “Midget House,” considered to be the origin of prefabricated housing, and have honed our technology and expertise over more than half a century while developing steel-frame and wooden homes.

The technical prowess we have cultivated in this way is reflected in high housing performance, including outstanding seismic resistance, exceptional durability, and energy efficiency.

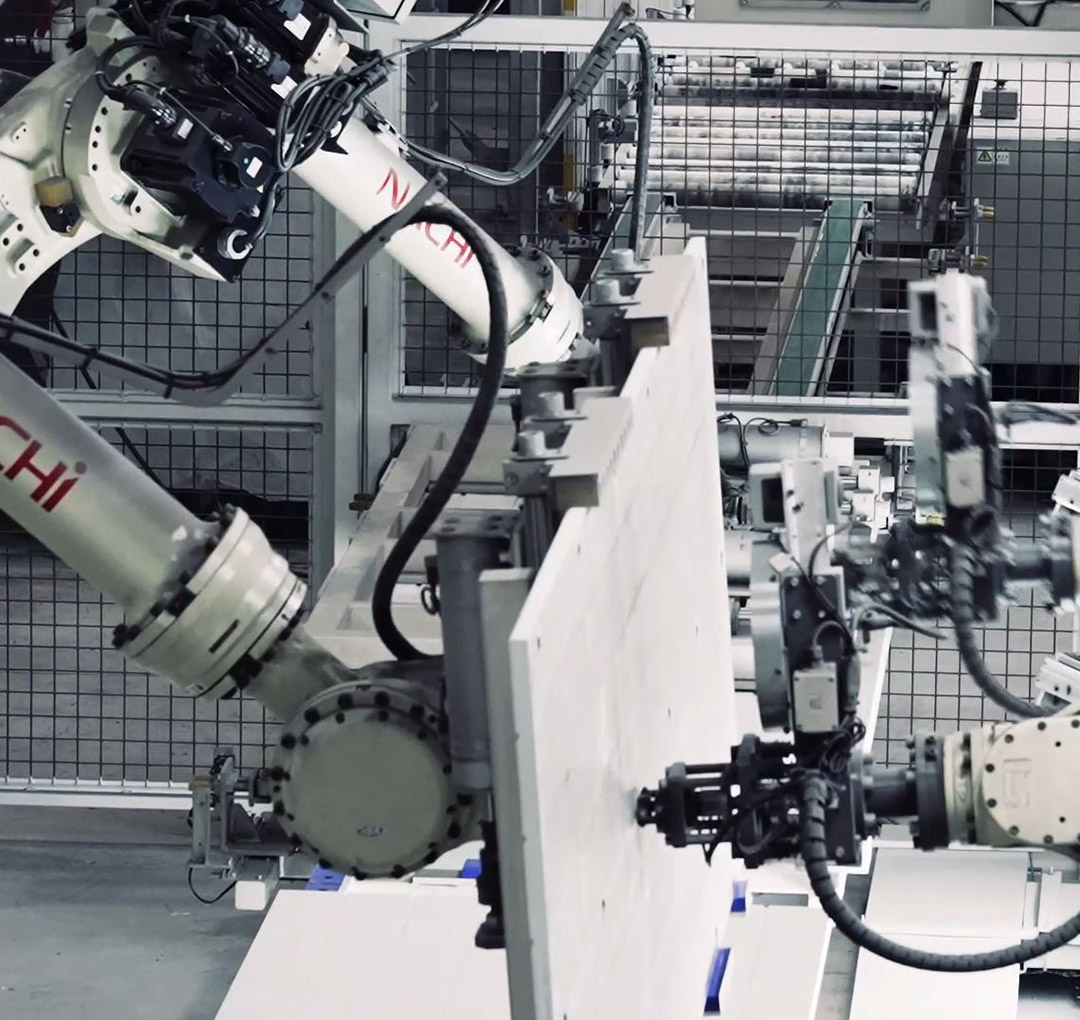

At our company-owned factories, a highly systematized production system where robots and skilled craftsmen collaborate enables the stable supply of high-quality, precision-engineered housing components. We swiftly deliver components to disaster-affected areas from our nationwide network of factories and supply chains.

We are also advancing pioneering initiatives in environmental considerations such as ZEH and ZEB, while contributing to the promotion of decarbonization through post-disaster public housing.

*As of March 31, 2025

(Kumamoto Earthquake: (“Minami-Kumamoto No. 2 Housing Complex ” in Kumamoto City, Kumamoto Prefecture))

(The torrential rains of western Japan: “Tenno Ohama Apartments” in Kure City, Hiroshima Prefecture)

(Great East Japan Earthquake: “Hara Renovated Rental Housing” in Okuma, Futaba-gun, Fukushima Prefecture)

Business development capabilities

(Great East Japan Earthquake: “Municipal Uomachi Irizawa Housing” in Kesennuma City, Miyagi Prefecture)

Business development capabilities

(The intense rains of July 2020: “Kamise Housing Complex” in Kuma-mura, Kuma District, Kumamoto Prefecture)

Business development capabilities

(Kumamoto Earthquake: (“Minami-Kumamoto No. 2 Housing Complex ” in Kumamoto City, Kumamoto Prefecture))

Business development capabilities

(The torrential rains of western Japan: “Tenno Ohama Apartments” in Kure City, Hiroshima Prefecture)

Business development capabilities

(Great East Japan Earthquake: “Hara Renovated Rental Housing” in Okuma, Futaba-gun, Fukushima Prefecture)

Housing technologies

Construction technology

Urban planning, multi-purpose development projects, and regional revitalization

Housing technologies

Construction technology

Urban planning, multi-purpose development projects, and regional revitalization